End Suction Pump

- Product Details

- Company Profile

ISO5199 End Suction Pump, Cost Effective. SDPUMP is APIQ1 Registered.

SCZ Type Process Pump

Standard: ISO5199

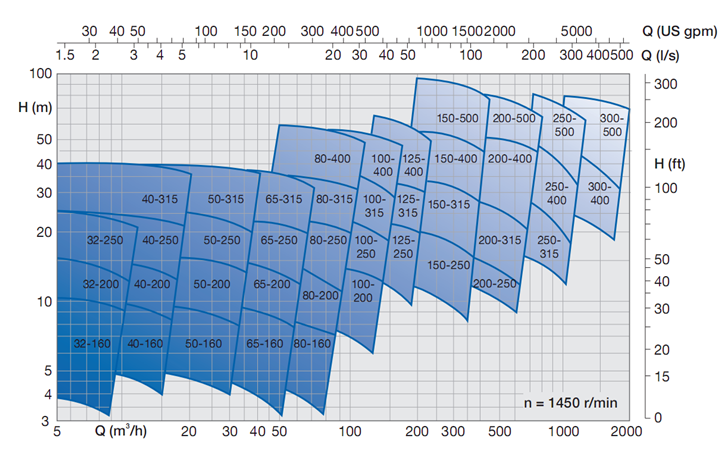

Flow: ~2000 m3/h

Head: ~160m

Pressure: 2.5MPa

Temp: ~150oC

Application:

This type of pump is suitable for conveying clean liquid or liquid contains small amount of particles, non corrosive or corrosive flammable, explosive and toxic media.

It is mainly used in chemical, petrochemical, refinery, coal chemical, power plant, paper industry, pharmaceutical industry, sugar industry, food processing, steel plant, waste acid treatment, urban water supply and drainage, and some other industries.

Product Description

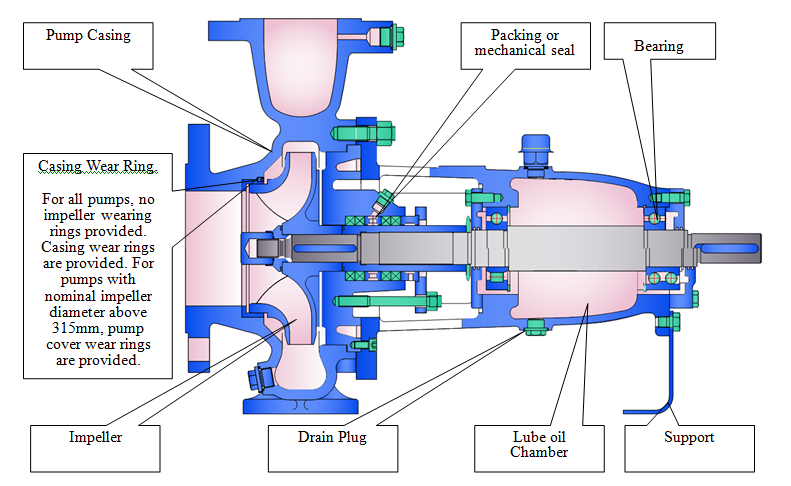

SCZ series standard process pump is a horizontal, single-stage, single suction, radial split, foot mounted process centrifugal pump, its size and performance meet ISO5199 standard. It is suitable for conveying clean and slightly polluted liquid, low and high temperature liquid, neutral or corrosive media.

Operation parameter

SCZ type pump

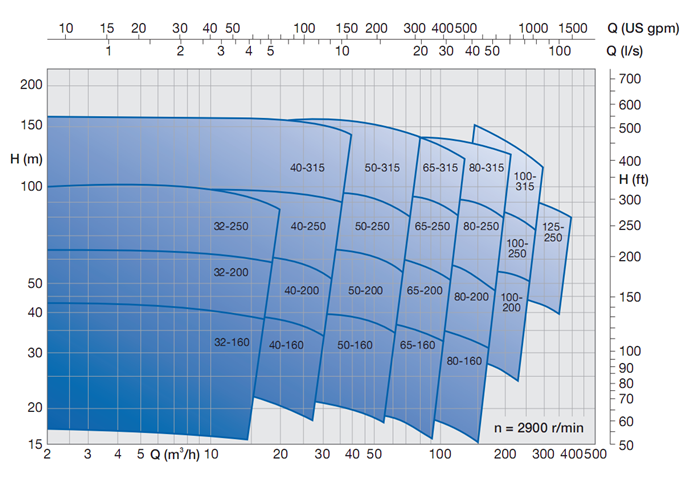

Nozzle Size: 32~300mm

Flow:~2000m3/h

Head:~160m

Pressure:2.5MPa

Temperature:~150oC

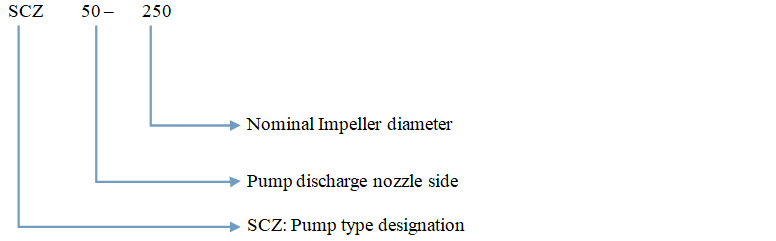

Pump Model Designation

Design Features

Hydraulic Design: The axial force is balanced by the expeller or balance hole; the pump body of some specifications is designed as double volute to balance the radial force

Shaft seal design: there are three types of standard seal forms, namely packing seal, single mechanical

seal and double mechanical seal, which can be equipped with various seal systems.

Structural design: full pull-out design, rear cover opening design, to ensure that bearing suspension components including shaft, impeller, shaft seal, etc. can be removed as a whole without removing the pump body and motor, only the extension of the coupling can be removed

Flange design: the pressure rating of the inlet and outlet flange is the same, PN2.5MPa. If the user needs to implement other standards, the flange sealing surface, connecting bolt and center can be implemented according to the requirements, and the large outer diameter and thickness of the flange shall be implemented according to the national standard.

Standard materials: Various kinds of standard materials available, API material grade S-5 (carbon steel), A-7 (304 S.S), A-8-1 (316SS), A-8-2 (316L SS), D-1 or D-2, etc.

Rigid design of pump shaft: heavy cylindrical roller bearing and a pair of double angular contact ball bearings are selected, which can not only bear larger radial load and axial load, but also strengthen the overall rigidity of pump shaft. At the same time, the dynamic balance of impeller is checked and corrected.The pump has small running vibration and low noise, which is very beneficial to the service life of shaft seal and bearing.

Bearing box design: large capacity oil storage chamber, constant oil level gauge and magnetic safety vent plug are used to ensure the lubrication and cooling effect of the bearing. The oil-resistant rubber seal with framework lip on both sides of the bearing box can keep the lubricating oil in the bearing box clean.

Auxiliary system: the auxiliary flushing system of SCZ standard process pump and mechanical mechanical seal meets the requirements of Appendix D of API610.

Material

The main parts of SCZ standard process pump are pump body, pump cover, impeller. These parts are in contact with the pumping medium, corroded by the medium, and bear the pressure and heat load of the medium. The material of these parts is very important for the safe and reliable operation of the pump. Therefore, it is necessary to select the appropriate material of the flow passage parts according to the different pumping medium and service conditions. When ordering, please provide the details of the pumping medium or point out the clear material requirements.

Performances

Experience Member

Experience Member 0

0 Chinese Supplier

Chinese Supplier